Extrusion-based 3D printing using Computational Fluid Dynamics

An open-source research initiative to achieve realistic predictions for fluid-based additive manufacturing.

Prof. F.A. Gilabert

Overview

This initiative, led by Prof. Gilabert, develops high-fidelity simulations of the 3D printing process that focus on the extrusion of fluids with complex rheology. Using computational fluid dynamics, these simulations integrate multiple open-source software tools to enhance feature flexibility.

Note: This website is regularly updated with examples, features, team members, publications, associated funding, etc.

Update - January 2026: Added a new example (number 7), added section "Publications", added new team member (Danna Villca)

Initiative timeline

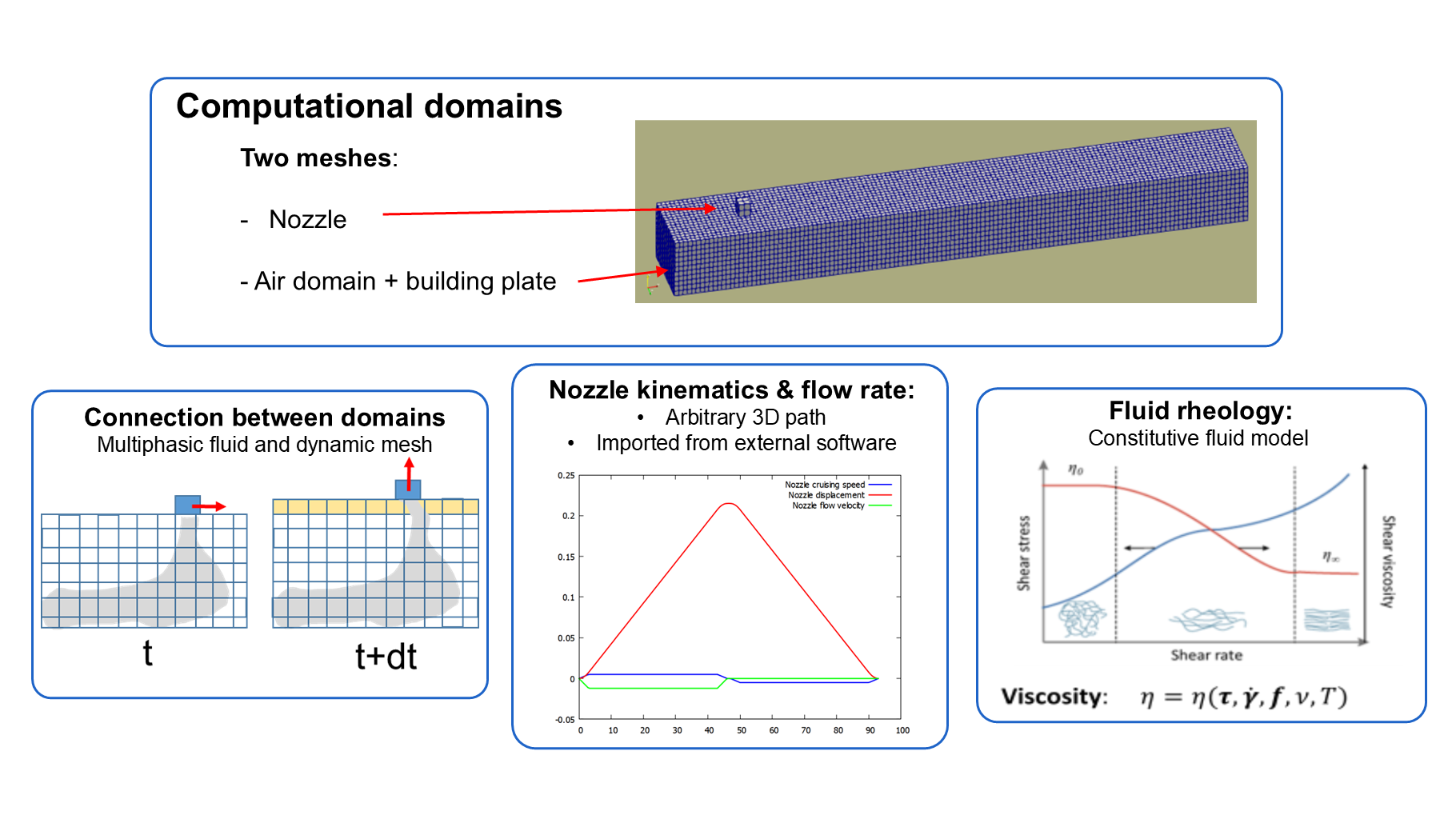

Modeling elements

Four essential elements are required: 1) Definition of at least two computational domains: the building region and the nozzle. 2) Interaction between these domains, detailing fluid transfer and boundary conditions. 3) Control of movable elements, mirroring a real printer. 4) Physical properties of the fluid, critical to the process.

Simulation examples

Below are some simple, representative examples demonstrating how our initiative can simulate real structures. More advanced features are available but not shown here. These examples, run on a conventional laptop, have passed mesh convergence tests.

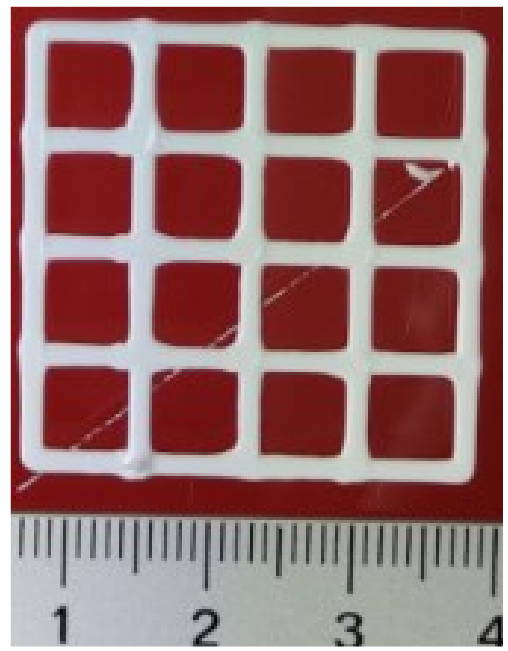

Example 1: Printing a grid to assess accuracy and the impact of printing parameters, including the introduction of a defective flow rate to understand its effect on construction uniformity. The accompanying photo belongs to the beautiful experiment conducted by Ta et al. 2023.

Example 2: Construction of tubes with square and circular cross-sections of different size ratios to nozzle diameter.

Example 3: 3D printing of a dome with an elliptical section, examining the effect of a deliberate error in the extruder's path to study the stability of the resulting deformation.

Example 4: 3D printing of a twisted, square-shaped tower consisting of 30 layers, with each successive layer rotated by 3 degrees.

Example 5: Simulation of helical coextrusion of a fluid mimicking fresh rice dough filled with strawberry syrup. The accompanying video corresponds to the helical extrusion (without co-extrusion) of a Sakinalu (traditional Indian snack), source: ROWBOT.

Example 6: Simulation of a double-nozzle system that deposits two pastes with different viscosities. The center of the double nozzle follows a zig-zag path, as shown in the companion image, and three layers are deposited. The gray paste is deposited during the first half of the trajectory, while the blue paste is deposited in the second half.

Example 7: Simulation of the word "CFD" being printed in 5 layers, using a non-Newtonian fluid with a gel-like consistency. The interface mesh is shown for reference. Companion figure presents a newly developed multiplatform Toolpath and Flow-Rate Editor, which allows users to design custom nozzle trajectories and configure time-dependent printing flow rates. The tool supports import and export to popular file formats and includes multi-fluid printing capabilities.

Collaboration

There are many things still to be investigated and implemented. So we welcome collaboration from researchers and institutions.

The following researchers are involved in this modeling initiative (listed in alphabetical order by surname):

- PhD candidate Elise Caron (Centre for Polymer and Material Technologies, Ghent University, Belgium)

- Prof. Koen Dewettinck (Food Structure and Function, Ghent University, Belgium)

- PhD candidate Laia Farràs-Tasias (Centre for Polymer and Material Technologies, Ghent University, Belgium)

- Prof. Francisco A. Gilabert (Mechanics of Materials and Structures, Ghent University, Belgium)

- Dr. Pei Hao (Mechanics of Materials and Structures, Ghent University, Belgium)

- Prof. Flavio H. Marchesini (Centre for Polymer and Material Technologies, Ghent University, Belgium)

- Mr. Mohammad Odeh (Mechanical and Industrial Engineering Department, An-Najah National University, Palestine)

- Prof. Stéphane Panier (Laboratoire des Technologies Innovantes, Université de Picardie Jules Verne, France)

- Dr. Aseel Samaro (Additive Manufacturing Platform, Ghent University, Belgium)

- Prof. Bahaa Shaqour (Mechanical and Industrial Engineering Department, An-Najah National University, Palestine)

- Dr. Juan Miguel Tiscar (Institute of Ceramic Technology, Spain)

- PhD candidate Jules Topard (Laboratoire des Technologies Innovantes, Université de Picardie Jules Verne, France)

- Mr. Simon Vande Kerckhove (Centre for Polymer and Material Technologies & Mechanics of Materials and Structures, Ghent University, Belgium)

- Eng. Davy Van de Walle (Food Structure and Function, Ghent University, Belgium)

- PhD candidate Danna Villca Centellas (Mechanics of Materials and Structures and Food Structure and Function, Ghent University, Belgium)

- Prof. Xingyi Zhu (College of Transportation, Tongji University, China)

Publications

Contact information

Professor in Computational Mechanics

fran.gilabert@ugent.be

Research group of Mechanics of Materials and Structures (MMS)

Department of Materials, Textiles and Chemical Engineering (MaTCh)

Faculty of Engineering and Architecture (FEA)

Ghent University (UGent)

Tech Lane Ghent Science Park – Campus A, Technologiepark Building 46

9052 Zwijnaarde (Ghent), Belgium